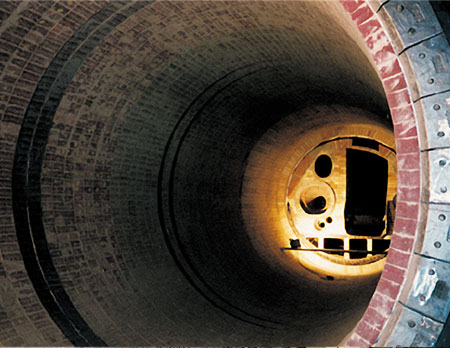

Chrome-corundum brick main mineral composition for alpha Al2O3 - Cr2O3 interstitial. Secondary mineral composition for the few compound spinel (or excluding composite spinel), chrome oxide content is 1% ~ 30% of refractory bricks. A piglet corundum bricks and sintering chromium chrome corundum bricks two kinds. Usually chromium corundum bricks is refers to sintering chromium corundum brick. In alpha Al2O3 as raw materials, join the amount of chrome oxide powder and chromium corundum clinker fine powder, forming, burn at high temperature. Sintering chromium just brick chrome oxide content generally lower than chrome casting corundum bricks. Still can use mud casting method for preparation, will alpha Al2O3 powder and chrome oxide powder evenly mixed, add solution glue and organic binder thick mud made, add the part with grouting chrome corundum clinker, legal, burn into brick-drying again. Can be used as glass kiln lining, wiredrawing glass flow flat bricks and used for liquid hole iron pretreatment devices, wastes incinerator, coal-water slur-ry pressurized gasifier backing, etc.

The application of chrome corundum bricks have more extensive application, one is the metallic chromium residue as the main raw material, produced by corundum bricks of chromium, the products are widely used in zinc smelting furnace, volatilization kiln corundum bricks, chromium has excellent ReZhen stability and high-temperature creep properties, also accord with national demand of cycle economy.

|